SERVICES

Materials Selection

Page under development

Recent Post

Experts Engineers Support

AMCO works through a corporate model of core staff and a pool of internationally known technical experts with practical experience, background and expertise.

Global Resources

AMCO is able to assist our customers globally in maintenance, asset management, digital transformation, product development and engineering support.

Customer Satisfaction

The reassurance to know you are working with a Winning Team. We are all working towards the same goal – our team is your team!

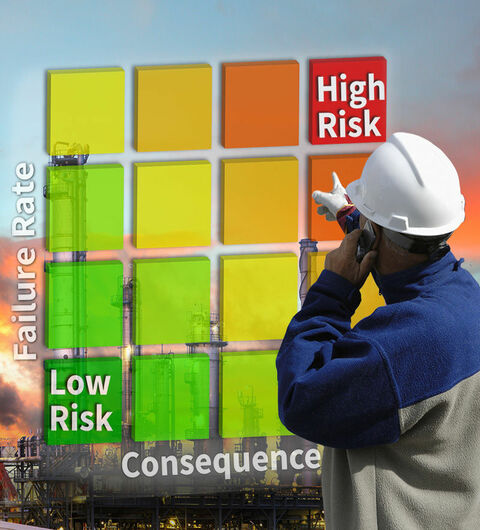

To alleviate the piping risk level, more and more companies, over the last decade, have adopted the risk-based inspection (RBI) methodology to reduce risk and improve cost benefits. This study applied RBI methodology to optimize the inspection strategy of the piping in a refinery and petrochemical plants. For detailed RBI studies, one needs to check the critical areas in which corrosions are expected. To monitor these areas, we need to have a corrosion loop system.

AMCO Integrity Pty Ltd has a very good experience in corrosion loop identification, please contact us today.

Get A Free Quote

We always bring good quality services with competitive price.

Other Related Services

Microbiological Induced Corrosion (MIC)

AMCO’s engineers, consultants and technical experts collaborate to offer microbiologically influenced corrosion (MIC) testing/analysis.

Failure Analysis/ Investigation

AMCO has a highly qualified team of metallurgists, mechanical engineers and corrosion specialists with experience in the analysis of component failures.

Corrosion Control and Prevention

AMCO experienced, professional staff along with its consultants has specialized expertise in corrosion technology and investigating corrosion-related failures.

Remaining Life Assessment

RLA is a method and procedure used to predict the remaining life of equipment, structures or facility that have been in service for an extended period of time.

Fit for Purpose Analysis

AMCO Integrity Pty Ltd assesses the fitness for service of the plant under operating conditions which can give advanced warning of in-service failures.

Risk Based Inspection (RBI)

AMCO RBI program is designed to both qualitative and quantitative criteria and is based on the American Petroleum Institute RP 580/581 inspection methodologies.