SERVICES

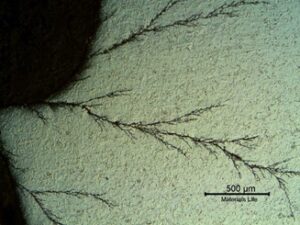

Failure Analysis/ Investigation

AMCO Integrity Pty Ltd’s also offers a comprehensive failure analysis service aimed at the identification of the damage and failure mechanism (s) (creep, fatigue, corrosion, metal dusting etc.), diagnosis of the root cause of failure, and making recommendations that will minimize the risk of repeat failures.

AMCO Integrity Pty Ltd has a highly qualified team of metallurgists, mechanical engineers and corrosion specialists with experience in the analysis of component failures in power plant boilers and turbines, oil refineries, petrochemical and process plant, offshore oil & gas, aerospace and other industries, and for a wide range of materials – from plain carbon and low alloy ferritic steels to 9-12%Cr Martensitic steels (such as P91), stainless steels, nickel-base alloys and aluminum alloys.

Recent Post

Experts Engineers Support

Global Resources

Customer Satisfaction

AMCO Integrity Pty Ltd’s team of specialists have the expertise to understand the interactions between the failure mechanism (s) and the material, design, operation and maintenance issues, to identify the root cause of failure and thus to make recommendations that will prevent similar damage and repeat failures in the future.

Recommendations may concern material selection and improvements in component design, quality assurance issues in manufacturing and welding, selection of weld consumables and welding process/parameters, and operating & maintenance practices.

We at AMCO Integrity Pty Ltd develop a detailed and comprehensive recommendations from these answers to produce practical cost effective recommendations that prevent failures, reduce processing costs and increase profits.

To support the findings of the failure investigation, AMCO Integrity Pty Ltd’s team can perform stress analysis, including Finite Element modeling, to establish actual stress levels that may have caused the failure to the complex component geometries and loading situations. Similarly, fracture mechanics methods can be applied retrospectively, using material properties data, to estimate the cracking rate and time to failure for correlation with the actual observations.

Get A Free Quote

Other Related Services

Fitness for Service (FFS)

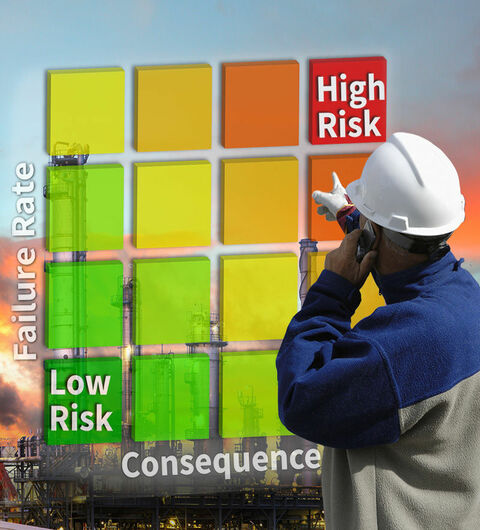

Risk Based Inspection (RBI)

Remaining Life Assessment

Corrosion Control and Prevention