Muhammad Hussain, Dr Tieling Zhang, University of Wollongong, Australia, Shahid Ali, AMCO Integrity Pty Ltd Australia and Dr Abrar Hussain, University of Science and Technology of China, Hefeu, P.R. China.

Pipelines are one of the most important energy transportation arteries and it is assumed they will continue to be a secure tool for energy transmission for many more decades. Among the different pipeline systems, gas pipelines are most important and vital. Due to the requirements for higher safety and reliability, integrity management has become an important programme to manage risk and develop proper inspection planning. This article gives a review of pipeline integrity management frameworks/processes used in the industry, and based on this, recommendations for using these frameworks/processes are given that will provide a guide for the pipeline operators and managers to improve their practices.

Recently, pipeline integrity saw the introduction of many advanced technologies to detect anomalies, enhance the efficiency of pipeline operation and reduce failures. Pipelines and accessories are valuable assets, generally owned, operated, and maintained by pipeline companies and in most countries around the world pipelines are an irreplaceable core of a gas or other materials transportation system, and a means by which gas or fluids are delivered from the source of supply to the customer.

Gas pipeline integrity management means a gas pipeline free of any defects, no leaks, and an incident-free operation of the pipeline system, to ensure it will not have an effect on health, safety, environment, business loss, company reputation, production and financial loss.

According to DNV-RP-F116, pipeline integrity is the system’s ability to operate safely and withstand the loads imposed on it during its lifecycle. If a system loses this ability, a failure can occur.

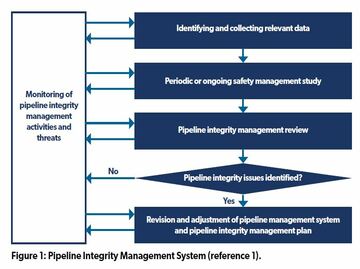

Pipeline networks are undeniably superior to other transportation systems, for instance, truck, train, etc. due to their cost effectiveness, security, higher reliability, safety and environmental friendliness over long distances. With all these aspects, pipeline infrastructures represent a high capital investment and due to this, pipelines must be free from the risk that could cause potential threats to life, or harm environment. Pipeline integrity design, monitoring and management become crucial to its operation (see Figure 1). For example, improper maintenance of natural gas pipelines may cause explosion and fire resulting from pipeline leaks or perhaps rupture (e.g., References 2 and 3).

Asset integrity management has been described as the continuous assessment process applied throughout the design, construction, installation and operation phases, to assure that the facilities are, and remain to be, fit for purpose. The aim of the asset integrity management process is to provide a framework for the following:

- Compliance with company standards, regulatory and legislative requirements

- Assurance of technical integrity by the application of risk based or risk informed engineering principles and techniques

- Delivery of the required safety, environmental and operational performance

- Retention of the License to Operate

- Optimisation of the activities and the resources required to operate the facilities whilst maintaining system integrity

- Assurance of the facilities’ fitness for purpose

Different energy pipeline asset management systems have been developed. Reference 4, for example, provides a holistic approach for energy pipeline asset management where the asset management system, asset management lifecycle activities and asset management procedures are presented and discussed in detail. It provides a guideline for energy pipeline owners and operators to manage their pipelines for safe operation.

Pipeline Integrity Threats

According to ASME B31.8S (Reference 5), there are 21 threats, nine categories of failure types, and three time-related defect types that could compromise the integrity of a natural gas pipeline. These nine classifications of failure types are:

- Manufacturing defect

- Materials and construction defects

- Stress corrosion cracking

- Internal corrosion

- External corrosion

- Equipment and related defects

- Third-party perpetrated damage

- Incorrect operations, maintenance and procedures

- Weather-related, earth-related and other outside unforeseen forces

The incidents reported can be broken down according to category, for example, gas leaks (40%), fire (14%), un-approved installation (13%), pipe damage, but no rupture (13%, other (20%), and by cause, 3rd party (60%), network integrity failure (20%), non-compliant installation (17%) and operator

error(3%).

Gas pipeline metal loss due to corrosion is the biggest threat to pipeline integrity programmes. Corrosion constitutes to the first three threats to liquid and gas pipeline systems highlighted above. It has been reported that about thrity three of the reported cases of hazardous gas transmission incidents

are due to corrosion. Common forms of corrosion on transmission gas pipelines are;

- Uniform corrosion,

- Pitting corrosion,

- Cavitation and erosion corrosion,

- Stray current corrosion,

- Microbiologically influenced corrosion.

Pipeline Integrity Management System (PIMS)

PIMS are basically programmes describing a company’s approach to pipeline integrity, and driven by the organisation’s engineering function to ensure the defined integrity goals, objective and targets are met, while ensuring the safety of public and environment. (Reference 6)

Pipeline Integrity requirements

Pipelines are of an effective means of gas transportation, but if a failure occurs, it can be expensive, involving loss in production, business loss, damage to reputation and environments. Pipeline integrity management is something that can help to optimise the operational costs and control the risk, by providing enhanced pipeline integrity through inspection, testing and analysis.

In the pipeline integrity management process, parameters related to pipeline performance assessment, inspection, defects, and repair and maintenance, are all considered in building a successful PIMS. Different pipeline systems have different requirements and a programme may contain:

- A process for identifying the pipeline segments that could have high consequences if failure occurred

- A baseline assessment plan

- An analysis that integrates all available information about the integrity of the entire pipeline and the consequences of a failure

- Criteria for repair actions to address integrity issues raised by the assessment plan and information analysis

- A continual process of assessment and evaluation to maintain pipeline integrity

- Identification of preventive and mitigation measures for protecting against failure in the areas of high consequence

Integrity Management Process

As stated above, gas pipeline integrity management is a process to avoid any failures through activities like inspection and repair, and to assist pipeline operators in enhancing their assets with longer service life and higher reliability. With entire economies built on reliable pipelines, their integrity is receiving more and more attention in management.

Any integrity management process should include the following steps:

- Identify potential pipeline impact by threat

- Gathering, reviewing, and integrating data

- Risk assessment

- Integrity assessment

- Responses to integrity assessment, mitigation (repair and prevention), and setting inspection intervals

- Update, integrate, and review data

- Re-assess risk

By completing above steps, a detailed integrity management plan can be developed. Such plans will address prevention, detection, and mitigation practices to avoid failures on pipelines. Improvements in asset management can bring a huge benefits by possibly reducing the maintenance cost through proper planning, selecting the right inspection tool, using qualified people, and maintenance and refurbishment of existing infrastructure to extend its economic and safe life. One of the major concerns with the integrity of the pipeline is the risk associated with leakage and explosion which must be kept as low as possible. The importance of asset performance in terms of its capability to transport gas may be less of a management issue than ensuring the integrity of the pipeline.

Risk-based Management of Gas Pipeline

Risk is defined as the probability of an event that causes a loss and the potential magnitude of that loss. Risk changes with changes in either the probability of the event, or the magnitude of the potential loss. To perform risk-based management, an analysis of the causes of the risks and an estimation of the failure probabilities need to be carried out, as well as a consequence analysis performed (Reference 7).

A key outcome of the pipeline’s asset management plan is to ensure that pipelines are managed effectively and efficiently in the long term by striking an optimum balance between performance, cost and risk, which is the strategy adopted in the new international asset management standard, ISO 55001. For pipeline integrity management, probabilities typically refer to the probability of pipeline failure due to certain defect growth. The consequences are related to the costs incurred by activities like inspection and maintenance, loss of productivity, rehabilitation and investigation, damage to the environment and community, environmental cleaning up, etc.

When considering the threats on pipelines, a number of barriers can be constructed to ensure the threat will not cause an incident in piping system. Most systems have multiple barriers that prevent a threat from causing an incident or failure.

Pipeline Inspection Management

Pipeline inspection is an integral part of pipeline integrity management system. Detailed inspection is the key to safe and reliable pipeline operations.

Most common inspection techniques used for pipeline integrity assessment are;

- Pigging,

- Hydro-testing

- External corrosion direct assessment (ECDA)

- Internal corrosion direct assessment (ICDA)

- Advanced NDT techniques like Air Drones etc.

Conclusion and Discussion

Pipeline owners or operators around the world have as their primary objective to transport commodities in a safe and reliable manner. There has been high investment by regulators, operators, and vendors to detect and mitigate any risks and develop robust preventive measures. This article has given a general overview of an energy pipeline integrity assessment/management system using quality management system tools to develop a framework to deal with all associated risks on a pipeline. Pipeline integrity can be achieved and managed efficiently through the analysis of different threats or hazards that might cause risks to pipelines. Based on hazard identification, risk assessment techniques are can be applied, and appropriate pipeline integrity monitoring and assessment methods conducted both internally and externally. A knowledge structure and process engineering approach is proposed for pipeline integrity management.

References

1. AS2885 (2008). Australian Standard: Pipelines-Gas and Liquid Petroleum.

2. ‘Natural Gas Pipeline and Infrastructure Explosions Nationwide’, Available: https://www.greenamerica.org/natural-gas-pipeline-and-infrastructureexplosions-nationwide (accessed in January 2020).

3. Pipeline and Hazardous Materials Safety Administration (PHMSA), Pipeline Incident 20 Year Trends,.

4. Khaled El-Akruti, Tieling Zhang, Richard Dwight, Maintaining Pipeline Integrity through Holistic Asset Management, European Journal of Industrial Engineering, Vol. 10, No. 5, 2016, pp. 618-638.

5. ‘Managing System Integrity of Gas Pipelines’, ASME B31.8S 2001. Supplement to ASME B31.8, ASME International, New York, USA. See also K Leewis, ‘Integrity Management of Pipelines’, International Pipeline Congress, Mérida, Mexico, 2001.

6. Rafael G. Mora, Phil Hopkins, Edgar I. Cote, Taylor Shie, Pipeline Integrity Management System, A Practical Approach, ASME Press 2016, USA.

7. W. Kent Muhlbauer, Pipeline Risk Assessment The Definitive Approach and Its Role in Risk Management, Clarion Technical Conference LLC, Feb. 2015.