SERVICES

Remaining Life Assessment

AMCO Integrity Pty Ltd has established in expertise in the Life Assessment of components from Oil and Gas, Petrochemical, Refining, Power Stations, Chemical, Processing, Fertilizer operating in creep regime.

We can assess the remaining life of plant components under operating conditions, offering real increases in safe operating life or increase in inspection intervals where appropriate. Advanced warning of creep, creep/corrosion and creep-fatigue failures can avoid expensive unplanned outages while avoiding undue maintenance or premature replication surveys. Improved repair welds, including cold weld repairs, can reduce the delay in returning a plant to service and may be suitable for long-term service, thus avoiding replacement at the next scheduled outage.

The determination of maintenance costs relating to equipment life extension requires an assessment of the remaining life in critical components. Maintenance recommendations can then be made to extend equipment life for the desired period. The analysis will include recommendations for future preventative maintenance scheduling, operating condition improvements, repairs, and replacement.

What is Remaining Life Assessment (RLA)?

Remaining life assessment (RLA) is a method and procedure used to predict the remaining life of equipment, structures or facility that have been in service for an extended period of time, usually close to or beyond the design life. The RLA offers a possible tool to estimate the useful remaining lifetime and avoid premature failure or scrapping of the part.

What is Life Extension?

Life Extension analysis is a further step or effort to extend the calculated remaining life of the equipment or facility until its economic life is met. The extension procedure could involve various actions of maintenance, repair, replacement, or downrate decision-making.

Recent Post

Experts Engineers Support

Global Resources

Customer Satisfaction

What is Life Extension?

Life Extension analysis is a further step or effort to extend the calculated remaining life of the equipment or facility until its economic life is met. The extension procedure could involve various actions of maintenance, repair, replacement, or downrate decision-making.

Remaining Life Assessment Technology can be used to assess:

- Boiler components

- Steam-turbine components

- Combustion turbine components

- Hydraulic turbine components

- Pressure vessels

- Welded structural components

- Storage tanks

- Pipes and pipelines

AMCO Integrity Pty Ltd provides full Component Life Assessment Service

Which can include the following;

- On-site inspection using advanced NDE

- Metallographic evaluation

- Review of design drawings

- Finite Element modelling and stress analysis

- Remaining Life Assessment calculations

- Development of inspection procedures

- Life Extension recommendations

- Weld repair (including advanced techniques for cold weld repair)

- Component replacements where appropriate

Get A Free Quote

Other Related Services

Fitness for Service (FFS)

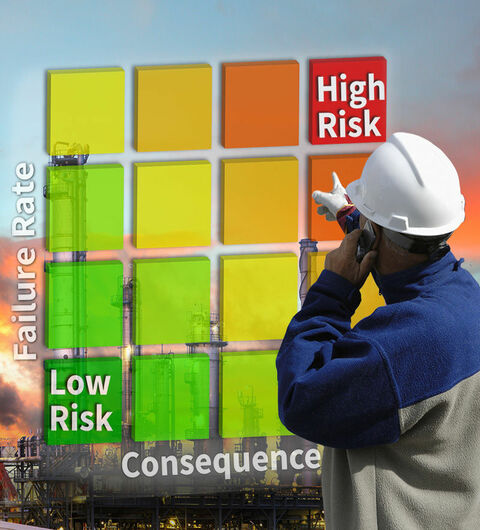

Risk Based Inspection (RBI)

Corrosion Management

Failure Analysis/ Investigation