SERVICES

Corrosion Loop Identification Services

What is Corrosion Loop?

Corrosion Loop Grouping of equipment and piping based on the same process condition (service medium, operating condition) and material selection criteria resulting in the same degradation mechanism.

What is Circuit?

Circuit Subsection(s) of a part of equipment or piping system where the metallurgy is the same and the corrosion rate is expected to be the same( e.g., shell, channel, running line, dead-legs, drain system, injection/ mixing point)

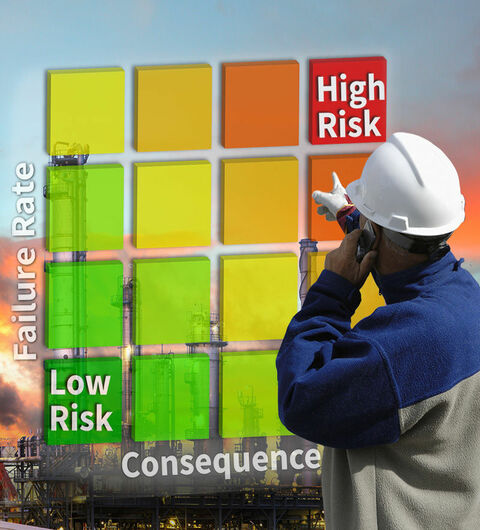

Corrosion loop(s) are systematized analysis “loops“ used during Risk-based inspection analysis. Both terms “RBI Corrosion loops” or “RBI corrosion circuits” are generic terms used to indicate the systematization of piping systems into usable and understandable parts associated with corrosion. Systematized piping loops or circuits are systems used in Risk-Based Inspection analysis to assess the likelihood and consequence of failure.

Other systematization may also prove useful, such as i.e. inspection, consequence, materials of construction, and chemistry.

The complex and extensive amount of piping in refineries, petrochemicals, fertilizers, power, and processing plants poses considerable difficulty in inspection planning.

Under-inspection or over-inspection might occur due to either the lack of jurisdictional requirements on the inspection interval and on the method for piping, or the inspection interval being only based on piping service classifications in the existing regulations, such as API 570.

This could result not only in much loss of resources but also unacceptable risks.

Recent Post

Experts Engineers Support

Global Resources

Customer Satisfaction

To alleviate the piping risk level, more and more companies, over the last decade, have adopted the risk-based inspection (RBI) methodology to reduce risk and improve cost benefits. This study applied RBI methodology to optimize the inspection strategy of the piping in a refinery and petrochemical plants. For detailed RBI studies, one needs to check the critical areas in which corrosions are expected. To monitor these areas, we need to have a corrosion loop system.

AMCO Integrity Pty Ltd has a very good experience in corrosion loop identification, please contact us today.

Get A Free Quote

Other Related Services

Risk Based Inspection (RBI)

Fit for Purpose Analysis

Remaining Life Assessment