AMCO Integrity Pty Ltd

Resource Hub

In this section you will find various technical articles written by AMCO experts that have featured in publications. We hope this can be an invaluable free information resource.

Impact of Covid-19 and needs of digital transformation to protect assets from corrosion

According to estimates, the virus slowed global economic growth in 2020 by roughly -3.2 percent on an annualized basis. Economic growth in most countries decreased drastically in the second quarter of 2020, swiftly rebounded in the third quarter, and has been largely positive since then.

The Threat to Pipeline Integrity from Soil Corrosion

The corrosion aggressiveness of soils and other areas has been a topical problem in transmission pipelines (both gas and hazardous liquids). Despite following best practices, corrosion and mechanical failures can still occur during operational, testing, and even construction phases, which may lead to loss of containment.

Application of big data analytics to energy pipeline corrosion management

Organisations around the world agree on the capability of analysing and using large and complex datasets which can give a significant competitive advantage in the 21st century in almost every field. The use of big data by the companies could be a smarter and more creative approach which has not been considered by pipeline companies

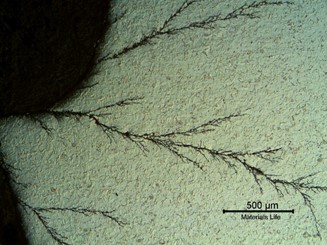

Stress Corrosion Cracking (SCC) is a threat to Pipeline Integrity Management?

In stress corrosion, most of the surface usually remains intact, however, fine cracks appear in the microstructure, making the corrosion hard to detect. The cracks typically have a brittle appearance and form and spread in a direction perpendicular to the location of the stress.

Corrosion behaviour of 304L NAG and 310L NAG in Nitric Acid

Austenitic stainless steels (SSs) have been used as structural materials for various components in the aqueous reprocessing plants. These alloys are widely used in nuclear-spent fuel reprocessing and waste management plants and the process fluid is nitric acid at temperature up to a boiling point.

An overview of energy pipeline integrity management, and future asset management strategies

Gas pipeline integrity management is to ensure a gas pipeline is free from incident in its operation, and also to ensure that any anomaly or defect does not have an effect on health, safety, environment, business loss, company reputation, or production and financial loss.

Failure Due to Cl-SCC of Austenitic Stainless Steels

Chloride stress corrosion cracking (Cl-SCC) is a type of SCC and is one of the well-known forms of SCC in the refining and chemical processing industries. This issue can be seen in austenitic stainless steels (SS) and depends on the environment and stress.

Evaluation of Stress Relaxation Cracking on 800HT Pigtails of the Steam Reformer

Stress relief cracking (SRC) occurs when susceptible alloys are subjected to thermal stress after welding to reduce residual stresses and improve toughness. Cracks were observed on the external surface of the outlet pigtails of a steam reformer.

Conference - CAMS 2018 – Advanced Materials and Manufacturing

CAMS2018 continues a series of meetings that evolved from cooperation between two eminent materials professional societies in Australia: Materials Australia (MA) and the Australian Ceramic Society (ACS). The forging of joint objectives has created a series of meetings that started in 2004.

Conference - Fabrication and use of P91 steel: international industry & plant experience

AMCO provides information on the condition of a component under ‘current’ and ‘planned’ future operating conditions enabling the operator to plan for the remaining life of that component.

Conference - GCC Reliable Plant Conference 2018- UAE

AMCO provides information on the condition of a component under ‘current’ and ‘planned’ future operating conditions enabling the operator to plan for the remaining life of that component.

Conference - Boiler Life Management (BLM)

AMCO provides information on the condition of a component under ‘current’ and ‘planned’ future operating conditions enabling the operator to plan for the remaining life of that component.